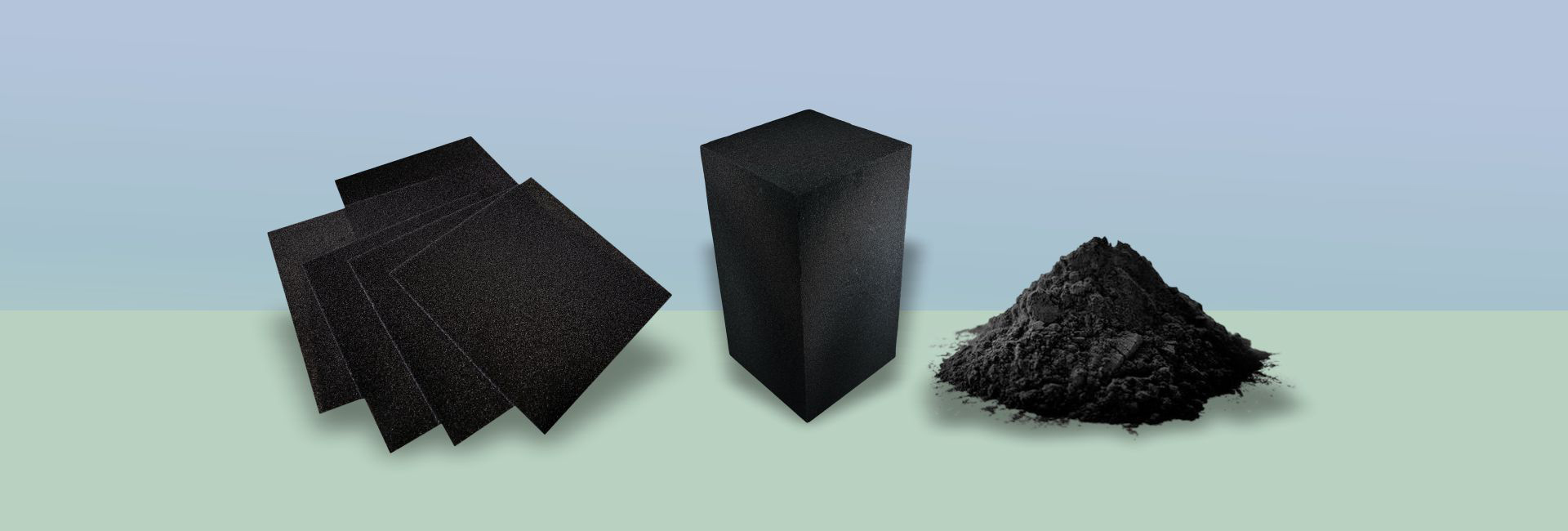

Reticulated Vitreous Carbon (RVC) Foam

What Is RVC Foam?

Reticulated Vitreous Carbon (RVC), also known as carbon foam, is a three-dimensional glassy carbon material with a unique, open-cell skeletal structure. It features ultrahigh internal porosity—typically97% void volume—and a rigid, reticulated network of ligaments. This open-cell structure offers superior permeability, conductivity, and stability, making it a go-to solution for industries that demand high performance under pressure. From aerospace insulation to energy storage, this material is designed to exceed expectations.

Advantages & Features

- High surface area + open pore structure enables efficient fluid/gas flow, excellent for filtration and catalysis.

- Chemical inertness: Glassy carbon resists acids, bases, solvents—even at elevated temperatures.

- Thermal robustness: Stable up to ~600 °C in air, ~3000 °C in inert atmospheres.

- Electrical conductivity makes RVC ideal for electrochemical applications like electrodes, super-capacitors, and fuel cells.

- Machinability and formability: Available in panels, rods, tubes; shapeable for custom tooling and sandwich panel cores.

Common Applications

Electrochemical & Energy Storage

Battery and super-capacitor electrodes, fuel cell supports—leveraging RVC’s high surface area and conductivity.

Filtration & Catalyst Substrates

Used in high-temperature gas filtration, molten metal filtration, and as catalytic carriers in harsh environments.

Thermal Management & Insulation

Found in aerospace insulation, thermal shock shields, furnace tooling, and cryogenic panels.

Structural Lightweight Components

Sandwich panel cores and composite tooling enjoy RVC’s stiffness-to-weight efficiency.

Defence& Stealth Technologies

Employed in radar-absorbing panels, blast-mitigation composites, and ablation surfaces.

Why Choose RVC Foam?

- Ultra-lightweight yet sturdy, with customisable mechanical properties

- Dual thermal and electrical performance

- Robust chemical resistance and thermal shock tolerance

- Customisable pore size and shapes—ideal for bespoke engineering needs